Cheaper Popular Sales Waste Paper Egg Tray Machine Egg Carton Forming Machine Equipment

Overview Product Description Brief Introduction The automatic egg tray production line is composed of pulping system, fo

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Size | Medium |

| Condition | New |

| Name | Paper Egg Carton Tray Forming Making Machine Quail |

| Final Shape | Customized |

| Final Size | Customized |

| Final Product | Egg/Cup/Bottle/Shoes/Coffee/Fruit Tray |

| Raw Material | Waste Parper/Pulp |

| Keywords | Quail Egg Tray Machine |

| Production Capacity | 5000pieces/Year |

Product Description

Product Description

Brief Introduction

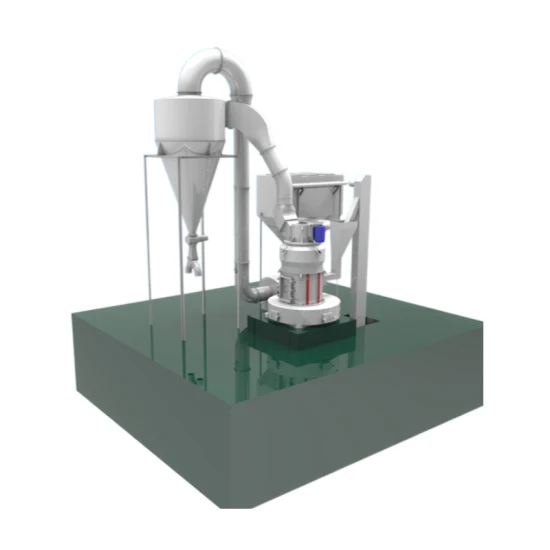

The automatic egg tray production line is composed of pulping system, forming system, drying system, stacking system, vacuum system, high pressure water system and air pressure system. It is specialized in producing 10, 12, 15, 18 egg boxes product. Using waste newspapers, waste carton paper, office paper, scraps and other waste paper as raw materials, through hydraulic disintegration, filtration, water injection and other processes to prepare a certain concentration of slurry, through the molding system on the special metal mold through vacuum adsorption A wet blank is formed, which is then dried on a drying line, and then stacked after being hot-pressed on-line.

Working principle:

Product Parameters

Model | Working Mode | Capacity | Drying System |

BYE0301 | Reciprocating Type | 800-1000 pcs/h | small handcart |

| BYZE0301 | Rotary Type | 800-1000 pcs/h | mesh belt dryer |

| BYE0401 | Rotary Type | 1000-1500pcs/h | mesh belt dryer |

| BYE0304 | Reciprocating Type | 2000-2200 pcs/h | small handcart |

| BYZE0304 | Rotary Type | 2000-2200 pcs/h | mesh belt dryer |

| BYZE0403 | Rotary Type | 2200-2500 pcs/h | mesh belt dryer |

| BYE0404 | Rotary Type | 3000-3500 pcs/h | mesh belt dryer |

Our Advantages

The roller drive and cold pressing of our molding machine are all controlled by servo motor and precision reducer to complete precise position control. This control method does not have the problem that the position of the drum cannot be accurately positioned due to mechanical wear. Thereby greatly improving the service life of the mold. And it is not easy to block the network, which improves the utilization rate of the machine.

Our machine adopts sub-transmission design. That is, the three parts of transfer, roller and cold pressing are completed by 3 servo motors. The three motors are organically linked through PLC, and can be turned on individually or jointly. Not only is the start-up operation simple, but the transfer speed can be greatly improved due to the separate control of the transfer, which greatly improves the output of a single machine.

The machine has a high degree of automation and a high safety factor. Once the machine fails, the machine will automatically stop. the design has a cold pressing mechanism. During the suction process, the machine is squeezed by a cold die, and the moisture in the product will be squeezed out, and it will be sucked out by vacuum at the same time. Compared with the products produced by machines without cold pressing, the water content is reduced by more than 6%--8%. Reduce the load of the drying room and save energy.

Packaging & Shipping

Company Profile

Baoyuan Machinery is a comprehensive enterprise that comprises R& D, test, manufacture, sales and service functions. We have succeeded in researching and supplying solutions with the following equipment: Drying equipment, building materials equipment, agriculture equipment and other products.

With our leading-edge technologies, advanced processing equipment and our corporate spirit of "innovation, pragmatism, unity, hard work and dedication", our company has the strength to meet the challenges from all aspects. We have the confidence to build "Baoyuan" into a world-renowned brand, provide quality services for the dryer and building processing industry, and achieve a win-win situation between the company and customers.