Small Stone Jaw Crusher Crusher for Calcium Carbonate Gypsum Limestone Quartz Graphite Calcite Feldspar Fluorite Powder Production Line

Overview Product Overview Introduction of jaw crusher Jaw Crusher is mainly engaged in crushing various rocks and stones

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | PE, PEX |

| Inlet Size | 250×1300mm |

| Condition | New |

| Warranty | 1 Year |

| After-sales Service | Technical Support |

| Small Jaw Crusher Warranty | One Year |

| Small Jaw Crusher Capacity(T/H) | 40-160,1-140 |

| Small Jaw Crusher Other Name | Jaw Crusher Machine |

| Small Jaw Crusher Model Number | PE |

| Small Jaw Crusher Weight | 5 T |

| Small Jaw Crusher Certification | CE |

| Small Jaw Crusher Finished Size(Mm) | 10-160 |

| Small Jaw Crusher Color | Optional |

| Small Jaw Crusher Place of Origin | Shanghai China |

| Small Jaw Crusher Brand Name | Clirik |

| Transport Package | Standard Container |

| Specification | CE |

| Trademark | CLIRIK |

| Origin | Shanghai |

| HS Code | 84742090 |

| Production Capacity | 1-140t/H |

Product Description

Product Overview

Introduction of jaw crusher

Jaw Crusher is mainly engaged in crushing various rocks and stones (such as limestone, calcite, barite, dolomite, potassium feldspar, marble, talc, gypsum, kaolin, bentonite, medical stone, phosphate, manganese ore, quartz, Activated carbon, glass, etc.) Coarse powder and small particles with comprehensive strength not higher than 320 MPa, widely used in metallurgy, mining, chemical industry, cement, coal, sand making, coal gangue, construction, refractory materials, ceramics and other industries.

Product Parameters

| Model | PC400x300 | PC600x400 | PC800x600 |

| Rotor diametermm | 400 | 600 | 800 |

| Rotor length mm | 300 | 400 | 600 |

| Rotor speedr/min | 1100 | 1000 | 900 |

| Max. feeding sizemm | <100 | <220 | <350 |

| Ouput sizemm | 5-10 | 5-15 | 5-20 |

| Capacity T/h | 5-13 | 10-20 | 18-30 |

| Motor powerKW | 11 | 18.5 | 45 |

| Number of hammerpiece | 16 | 20 | 28 |

| Weight T | 0.8 | 1.8 | 2.8 |

| Overall dimension L*W*H/mm | 900*670*860 | 1200*1050*1200 | 2360*1490*1415 |

Working Principle

Working principle of jaw crusher

1. The movable PE Series Jaw Crusher goes upward and downward through eccentric shaft when belt wheel are driven by the motor. 2. The angle between PE Series Jaw Crusher and bracket turns big when the PE Series Jaw Crusher goes upward,which pushes the PE Series Jaw Crusher plate to come closely to fixed jaw plate. 3. At the same time,materials are crusher with the movement of the PE Series Jaw Crusher. 4. When the PE Series Jaw Crusher goes downward,the angle between PE Series Jaw Crusher and bracket turns small. Under the force of spring and connecting bars,the PE Series Jaw Crusher plate leaves fixed jaw plate, and the crushed materials with qualified size are discharged from the crushibf cavity. 5. With the continuous rotation of the motor,the PE Series Jaw Crusher crushes and discharges materials,which,in turn,realizes the goal of mass production.

Product Advantage

Advantages of jaw crusher

| 1. Widely used in metallurgy, mining, chemistry, cement, construction, refractory materials and ceramics.2. CE, ISO9001, SGS3. High capacity, 5-200t/h.4. Uniform particle size5. High crushing ratio6. Long lifecyle of spare parts7. Testing hammer crusher before delivery is available |

Company Profile

Our Company

SHANGHAI CLIRIK MACHINERY CO., LTD located in PUDONG New district of Shanghai china, as a pioneer enterprise, which is specializing in research, manufacture and sales of all kinds of grinding mill, all kinds of crushers from coarse grinding mill, fine grinding mill and ultra fine grinding mill, grinding mill related equipment, such as powder modifying machine, powder packing machine. Powder conveying system, etc. We have devoted into grinding field for more than 30 years, we belive only focus can be professional.Our company has already formed a full set of modern production line, equipped with intelligent, standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

Custome visiting

Clirik has more than 12,000 square meters of standardized production plant, including processing workshop, assembly workshop, painting and sandblasting workshop, trial machine debugging workshop, finished product placement workshop, etc. The workshop is equipped with more than 100 high-end CNC machine tools of well-known foreign brands. From drawing, assembly to debugging, the equipment manufacturing has gone through thousands of processes, including resizing, cutting, grinding, trimming, heating, forging, turning milling, grinding and drilling, inspection, painting, assembly and test machine. Each manufacturing process is repeatedly verified by our engineers to ensure the reliability and integrity of each device.The customer was very satisfied with us after the visit.

Our Certification

We have received many special train certificates.

Our Service

Pre-sale service:1.Clirik provides a variety of mining equipment for you to choose from.

2.Clirik will recommend suitable production lines and grinding equipment to you according to your site.

3.Clirik customizes the logo and color of the grinding equipment according to your company image.

4.Clirik provides third party inspection to ensure the quality of your grinding equipment.

After-sales service:1. Clirik provides you with online installation and use videos.

2. Clirik will provide you with technicians to install and debug the grinding equipment.

3. Clirik trains you the technicians who use and maintain the grinding equipment.

4. Clirik provides you with a one-year warranty and lifetime service for the grinding equipment.

Our Other Product

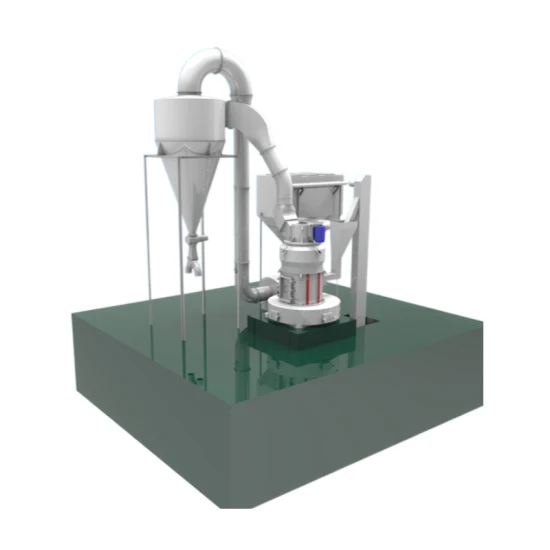

| Ultrafine vertical Roller Mill | Raymond Mill | Micro Powder Grinding Mill |

| Finished Size: 600-4500(mesh) Capacity: 3-20(t/h) Pass rate: D50 2 micron | Finished Size: 50-450(mesh) Capacity: 1-28(t/h) Pass rate: D90 30 micron | Finished Size:300-2500(mesh) Capacity:0.5-45(t/h) Pass rate: D97 5 micron |

FAQ

Please fill in your need products and your message and please do not forget mail and/or phone if you like to be contacted. We are the professional machine manufacturer in China with 30 years experience. Pls kindly check the following, in order to select a suitable machine, send you specific techinical data, quotation and the solution drawing for you.1. What is the raw material do you want to process?2. What is the capacity per hour do you need?3. What is the raw material input size?4. What is the output size of your product?

We hope you can tell us these details, we will give you the best quotation, technical data and solution drawing ASAP, thanks. Your satisfaction is our greatest pursuit, we would like to sincerely for your service! We look forward to your inquiry!

Related Products

-

![Amulite Making Fibre Cement Sheet/Cement Fiber Board/Cement Fibre Sheet/Cement Board/Calcium Silicate Board Production Line]()

Amulite Making Fibre Cement Sheet/Cement Fiber Board/Cement Fibre Sheet/Cement Board/Calcium Silicate Board Production Line

-

![2020 Fiber Cement Board Partition Wall Production Equipment Plant/Calcium Silicate Board Production Line]()

2020 Fiber Cement Board Partition Wall Production Equipment Plant/Calcium Silicate Board Production Line

-

![Cement Fiber Board Hastchek/ Flow]()

Cement Fiber Board Hastchek/ Flow

-

![Natural Gypsum Powder Production Line with Boiling Furnace Technology]()

Natural Gypsum Powder Production Line with Boiling Furnace Technology