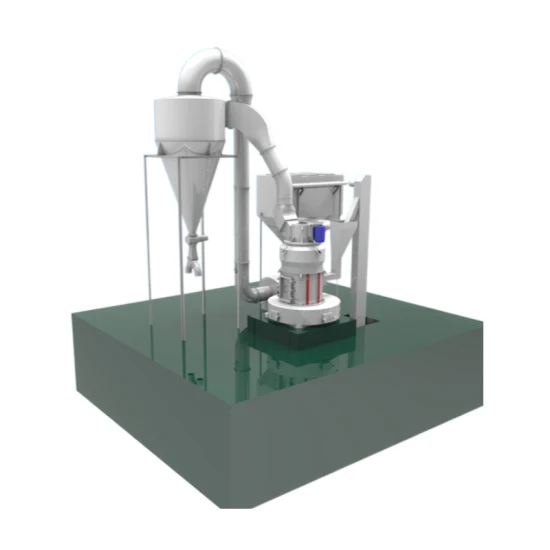

Natural Gypsum Powder Production Line Plant Equipment

Overview Product Description Features of this hot air boiling furnace technology1-Reduce investment2-Reduce maintenance

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | YR-GYP-P-006 |

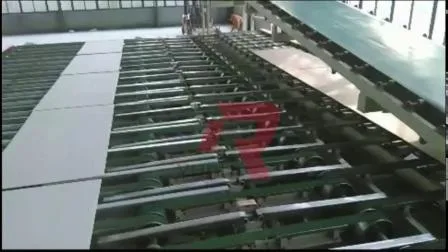

| Control Type | Gypsum Board Production Line |

| Crushing Degree | Ultra-Fine Mill |

| Automatic Grade | Full Automatic |

| Finished Product Features | Finished Powder Quality Uniformity and Stable |

| Application | Make Building Material Like Board , Cornice,Block |

| Raw Material | Natural Gypsum Rock /Fgd Gypsum / Phosphogypsum |

| Factory Visiting | Available |

| Payment | T/T L/C |

| Installation Time | 90 Days |

| Labors | 5-6 Labors |

| Famous Brand Used | Chinese Famous Brand or International Brand Custom |

| Technology | Hot Air Boiling Furnace or Rotary Kiln |

| Finish Product Type | Calcined Gypsum Powder &Plaster of Paris |

| Control System | PLC Simens or Customized |

| Product Name | Gypsum Powder Production Line |

| Capacity | 30,000 Ton to 400,000 Ton Per Year |

| Automation | Full Automatic |

| Transport Package | Sea Transportation Packing Method |

| Specification | Standard or Customized |

| Trademark | Yurui brand |

| Origin | Shandong |

| Production Capacity | 100 PCS / Year |

Product Description

Product Description

| Product Name | Gypsum Powder Production line |

| Annual capacity | 15,000 to 500,000 tons |

| Working time | 24h/day ,300day/year |

| Raw Material Gypsum Type | Natural gypsum ore |

| Gypsum powder Mesh | Within 220 meshes |

| Heating method | Hot air boiling furnace or rotary kiln |

| Application of the powder | Building material like to produce gypsum board , To make plaster of paris , to make gypsum cornice or ceiling |

| Degree of automation | Fully automatic |

| Final product specification | Gypsum powder |

| Fuel for the heating system | Natural gas,coal,diesel,heavy oil,light oil etc |

| Finished powder bending strength | 2.7 Mpa |

| Finished powder compressive strength | 5 Mpa |

Case project abroad

Case 1:1-Project name:Natural gypsum powder&board project2-Project capacity: Gypsum powder line:150000ton Gypsum board line : 10Million sqm/year 3-Project technology:hot air technology For this project, our Chief engineer has only taken 5 days to run the whole gypsum powder production line and put it into production after installation, and our customer also felt surprised on it. While some manufacturers need more than one month to finish it or even some are unable to run it for production.

Case 2: Chemical gypsum powder&POP projectThis is our chemical gypsum powder project in South Africa. The customer is a well-known local building material supplier. The owner has been in the phosphogypsum industry for more than 40 years.project capacity: Gypsum powder line: 50000 tons/year Plaster of Paris line: 30000ton /year | Case 3:project name:Chemical gypsum powder&POP projectproject capacity:400,000 tons/year-500,000ton /year 3-projecttechnology:hot air boiling furnace technologyThis project is one of our domestic projects with a large capacity of 400,000 tons. The raw material is chemical gypsum powder, and use the production process of hot air boiling furnace. This customer's factory is only 1 hour away from our company, and now he is currently building a second production line and its annual production capacity can be 500,000 tons.Actually we have succeeded more than 40 similar projects in our country. |

Case 4: Project name: Gypsum powder&board projectProject capacity: 4 factory ,8 lines totallyIn 2008 year: gypsum powder line 50000 tons/year + gypsum board line 8000000 m2/yearIn 2009 year: gypsum powder line 150000 tons/year + gypsum board line 10000000 m2/yearIn 2012 year: gypsum powder line 150000 tons/year + gypsum board line 10000000 m2/yearIn 2018 year: gypsum powder line 300000 tons/year + gypsum board line 20000000 m2/yearSince 2008, the boss purchased 4 gypsum powder projects from us, with capacities ranging from 50,000 tons/year (2008) to 300,000 tons/year (2018).He has now grown to become the largest producer of gypsum building materials in Indonesia, and the quality of his gypsum powder can compete directly with the local Knauf factory and even sell at a higher price. | |

It's not easy to visit the project in China now. But we have different project in different countries for visiting.

What we can help?

Company Profile

Hot air boiling furnace technology is NO.1 In China100% success rate of domestic and foreign projectsProject site visit and video viewing visit availableMaximum capacity can reach 400,000 to 500,000 tons per yearOver 15 years of experience in oversea market project service experience

How we differ ?

1-Rich experience :1) Experience in gypsum technology research since 19982) Experience of 100+ projects manufacture &install abroad and domestic2-Professional team1) Experts provide professional design for the project2) Market dept. members provide professional and efficient communication3) Experienced installation group gets projects into production quickly.4) the Whole group provide a powerful One-stop sourcing service3-Full range of services1) Pre-sales: full cooperation with pre-preparation work2) In-sales: on-time reporting of production progress3) After-Sales: Lifetime & 24h technical support4-Irreplaceable advantages1) Case projects visiting abroad on-site & online2) Training to workers & engineerFAQ

| 1. | Could you dispatch enginners to my plant for installation?Yes, of cause. Our engineers are in Africa to install 5 production lines now. When they finish the project, will go to Uz. |

| 2. | Could I visit your factory before order?We suggest you visit our running project abroad. Your could choose the one near to you to visit. |

| 3. | How many days do you need to produce the machines?Generally need about 60 days |

| 4. | How many days will it take to install the production line?About 90-100 dyas to install and try running |

| 5. | Could you help train our workers?Yes, our engineers will help on training, and will offer you full set of technology documents. |

| Additional support - Raw materials |

Related Products

-

![Egg Tray Pulp Molding Equipment From Factory Directly]()

Egg Tray Pulp Molding Equipment From Factory Directly

-

![Industrial Automatic Electric Plastic Egg Tray Washing Plastic Basket Cleaning Machine Automatic Processing Equipment]()

Industrial Automatic Electric Plastic Egg Tray Washing Plastic Basket Cleaning Machine Automatic Processing Equipment

-

![Wall Board Calcium Silicate Sheet Machinery Plant Production Line]()

Wall Board Calcium Silicate Sheet Machinery Plant Production Line

-

![Paper Faced Gypsum Board Production Line with German Technology]()

Paper Faced Gypsum Board Production Line with German Technology