Zenith Large Capacity Gypsum Powder Production Line

Package Size 700.00cm * 300.00cm * 400.00cm Package Gross Weight 10000.000kg Zenith Large capacity Gypsum Powder Product

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | MTM100, MTM130, MTM160 |

| Control Type | Artificial |

| Crushing Degree | Ultra-Fine Mill |

| Automatic Grade | Automatic |

| After-Sale Service | for Whole Using Year |

| Test&Installation | Engineer Assigned |

| Spare Parts Supply | for Whole Year |

| Mining Object | Grinding Machines |

| Transport Package | Container, Nude Packs, in Bulk |

| Specification | ISO9001: 2000 |

| Trademark | Zenith |

| Origin | China |

| HS Code | 8474209000 |

| Production Capacity | 3-20tph |

Packaging & Delivery

Package Size 700.00cm * 300.00cm * 400.00cm Package Gross Weight 10000.000kgProduct Description

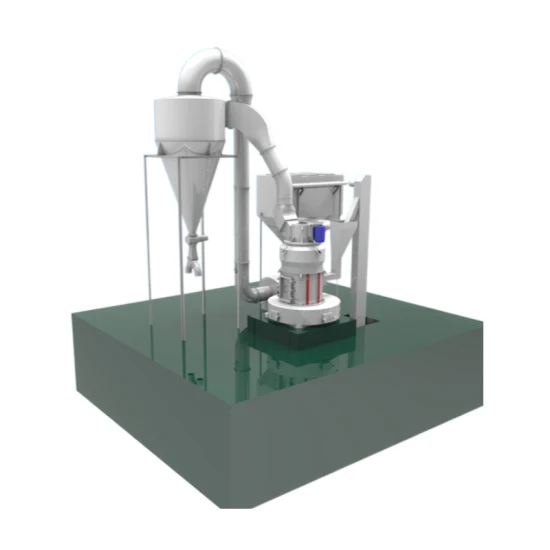

Zenith Large capacity Gypsum Powder Production LineGypsum Powder Production Line is made of jaw crusher, bucket elevator, electrovibrating feeder, main unit, optional equipment, blower, centrally electric control system, etc. According to customer's specific requirement, we can choose high pressure suspension grinding mill or MTM medium speed trapezium mill.

Gypsum Powder Production Line:

Materials first enter jaw crusher to be crushed to smaller size. Then they are lift to storage room by elevator. Vibrating feeder will feed materials into grinding chamber evenly and gradually. After being grinded, the powder will be blowed to cyclone by blower. Then the material will be transferred to storage room through pipes, and then will be discharged as final products. The whole process works in a negative pressure environment.

First, through pipes, the air from the blower enters the cyclone collector above the storage room along with powder, and then returns to the blower through return pipe. In the way, air can be recycled. There is a powder locking equipment under the cyclone, which isolates the outside positive air pressure and the negative air pressure inside cyclone. And this ensures high productivity.

In addition, the residual air and dust under the main unit will be transferred to dust catcher equipment through pipes and be cleaned there. The clean air will be discharged so that environment will be protected.

Gypsum Powder Production Line technical data:

| Name | MTM100 | MTM130 | MTM160 | |

| Ring roll number(pcs) | 4 | 5 | 6 | |

| Major diameter of roller(mm) | Φ310X170 | Φ410X210 | Φ440X270 | |

| Inner diameter of roller(mm) | Φ950X170 | Φ1280X210 | Φ1600X270 | |

| Revolving Speed(rmin) | 130 | 103 | 82 | |

| Max feed size(mm) | <25 | <30 | <35 | |

| Final size(mm) | 1.6-0.045 fineness can reach to 0.038 | 1.6-0.045 fineness can reach to 0.038 | 1.6-0.045 fineness can reach to 0.038 | |

| Output(th) | 3-8 | 6-11 | 9-22 | |

| Complete physical size(mm) | 7100×5900×7900 | 9200×7250×9700 | 12550×5700×8355 | |

| Main unit motor | Model | Y225S-4 | Y280S-4 | Y315M-4 |

| Power(kw) | 37 | 75 | 132 | |

| Rotate speed(rmin) | 1480 | 1480 | 1480 | |

| Centrifugal induced draft fan motor | Model | Y225S-4 | Y280S-4 | Y315M-4 |

| Power(kw) | 37 | 75 | 132 | |

| Rotate speed(rmin) | 1480 | 1480 | 1480 | |

| Classifier speed regulating motor | Model | YCT200-4A | YCT200-4B | YCT250-4A |

| Power(kw) | 5.5 | 7.5 | 18.5 | |

| Rotate speed(rmin) | 125-1250 | 125-1250 | 132-1320 | |

| Elevator | Elevator model | TH210 | TH210 | TH315 |

| Motor model | Y100L2-4 | Y100L2-4 | Y112M-4 | |

| Power(kw) | 3 | 3 | 4 | |

| Rotate speed(rmin) | 1430 | 1430 | 1440 | |

| Jaw Crusher | Jaw Crusher Model | PE200×350 | PE250×400 | PE250×750 |

| Main unit motor | Y160M-6 | Y180L-6 | Y200L2-6 | |

| Power(kw) | 7.5 | 15 | 22 | |

| Rotate speed(rmin) | 970 | 970 | 970 | |

| Magnetic vibrating feeder | Main unit motor | GZ2F | GZ3F | GZ3F |

| Power(kw) | 0.15 | 0.2 | 0.2 | |

Related Products

-

![Egg Tray Equipment Hot Sale]()

Egg Tray Equipment Hot Sale

-

![Industrial Automatic Electric Plastic Egg Tray Washing Plastic Basket Cleaning Machine Automatic Processing Equipment]()

Industrial Automatic Electric Plastic Egg Tray Washing Plastic Basket Cleaning Machine Automatic Processing Equipment

-

![2020 Calcium Silicate Board Manufacturing Machine/ Fiber Cement Board Making Machine/Production Line]()

2020 Calcium Silicate Board Manufacturing Machine/ Fiber Cement Board Making Machine/Production Line

-

![Fiber Cement Board/ Calcium Silicate Production Line with 3 Million Square Meters Capacity Per Year]()

Fiber Cement Board/ Calcium Silicate Production Line with 3 Million Square Meters Capacity Per Year